This is the third in a series of blog posts highlighting what Groundworks teaches patrons about 3D printing. This page will give you a brief introduction to mesh repair software so you can check your STL/3MF file for errors before 3D printing. Keep reading below or skip to another step using the following links:

Step 1: What is 3D Printing?

Step 2: Find/Design a 3D Model

Step 3: Check For/Repair Errors

Step 4: Slicing Your Model

Step 5: Choosing the Best Filament

Step 6: Print Your Model!

Why do I need to check my STL or 3MF file for errors?

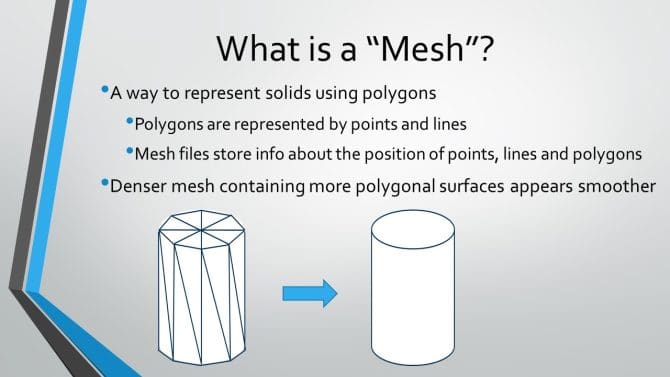

The “mesh”, or outer shell, of a 3D model must be free of errors. All faces of the object must be connected to each other without any gaps. When these faces aren’t connected, the gaps or holes in the mesh can adversely affect the quality of the print.

Auto-Repair Using PrusaSlicer

You'll learn more about PrusaSlicer in Step 4: Slicing Your Model when we discuss preparing your model for 3D printing, and it should be your primary way of checking 3D models for errors and fixing them. PrusaSlicer will automatically repair models to a certain degree, but it may be necessary to fix the model using a dedicated service or downloading a separate piece of software.

After you import your model to PrusaSlicer, a warning symbol may appear next to the model name if there are errors. You can either right-click on the warning symbol (left picture green arrow) or right-click on the model itself and select "Fix through Netfabb" or "Fix by Windows repair algorithm" (right picture red square).

After you repair your model, be sure to double check it. PrusaSlicer's auto-repair feature can't fix everything and may delete some parts of a model in order for it to print properly. If you don't notice a difference between your original model and the repaired model, that's a good thing! You're ready to go to Step 4: Slicing Your Model. If you inspect your model and certain features mysteriously disappeared or don't look like the original model, you may need to use a dedicated mesh repair software to figure out why and to repair the file.

Mesh Repair Software

If you don't use a slicing software that features a built-in auto-repair tool, Formware and Aspose both offer free web-based programs that detect and repair defects from uploaded STL files. They do have some limitations, and, if they aren't able to repair your file, it's likely your model is far from a closed shell and the better approach would be to manually fix it in a CAD software or one of the other pieces of mesh repair software below.

Meshmixer - From Autodesk, Meshmixer provides mesh editing, repair, and analysis features, in addition to giving you the ability to design models from scratch. Meshmixer also has a number of tutorials, a user manual, and a robust community forum. It's no longer in active development as Autodesk continues to integrate its tools into Autodesk Fusion, but the company still makes the software available for free.

Here is a quick tutorial from Prusa Research using a few different mesh repair programs. Of the three, Meshmixer will give you the most control over your edits.

You can check out the full Meshmixer tutorial on Prusa Research's blog.

If you want to learn more...

Understand and Fix Common STL File Errors - 3D Hubs' guide provides short videos and quick explanations of the most common types of STL errors.

3D printer manufacturer, Formlabs, provides an overview of five (5) free STL repair tools and a text based Meshmixer tutorial offering 15 tips to edit and repair STL files. Maker's Muse has a an old, but still relevant, video tutorial Fixing Impossible STLs with Meshmixer.

Autodesk is no longer developing Meshmixer and is integrating its repair features into Fusion (FREE for non-commercial hobbyists). Here's a YouTube video detailing how to repair mesh files in Fusion.

Last Updated 1/22/2022